SAMPLE PREPARATION LABORATORY

Intro

Specimen preparation for geochemical analyses and microstructural examination involves a series of operations, the ease and success of each depends on the preceding step. The first cut impacts all subsequent steps and the impact can be quite detrimental if too much damage is induced during sectioning. Using its on-site saws, mounting, laps and polishing equipment, the Petro-Volcanology Research Group produces high-quality polished sections, blocks and wafers of natural, experimental and industrial materials. The maximum time required for the preparation of one sample from raw material to a ready-to-analyse polished section is 15-20 minutes, on average.

EQUIPMENTS

Instrumentation

- Raw cutting, drilling, and milling machines

- Precision cutting machine Remet Micromet M

- Compression mounting machine Microconsult (MCR-2550)

- Lapping and polishing machine Remet LSA (LS2) automated jig

Raw cutting, drilling, milling

Description

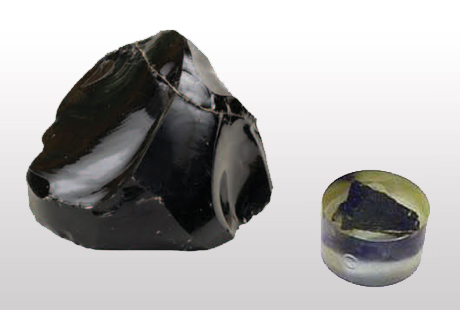

A standard set of conventional machines is used in the preliminary preparation of samples. When necessary, rocks, glasses, and other materials are cut by diamond cut saw to reduce their size for the next steps of sample preparation. In most cases, core drilling is required for both natural and experimental samples. This operation is performed using a precision core picker equipped with a large set of drill bits with diameters from 2 to 50 mm. Milling though a planetary mill is used for comminution of materials, down to colloidal fineness. Both mortars and grinding balls are in agate to minimize any possible contamination of the sample during milling.

Precision Cutting

Description

The Remet Micromet M diamond cut saw allows us to obtain smooth cuts on natural and industrial materials. Sample of any roughness can be cut thanks to a wide range of sample holders. Cutting is the very first step of sample preparation and the high quality of our cuts ensures no damage of the sample surface and speed in the next steps of mounting and polishing.

Mounting

Description

The primary requirements for mounting are ease of handling and edge retention. Our Microconsult (MCR-2550) compression mounting machine allow us to mount samples precisely into a resin block for further lapping and polishing. The sample is placed in a circular mould and impregnated with a resin, ensuring the top and base of resin blocks are parallel. Resins of different hardness can be used depending on sample characteristics.

Lapping and polishing

Description

Lapping, and polishing are the final steps in sample preparation. These operations must be carried out with maximum care to avoid any damage of the sample. We perform these steps with a Remet LSA (LS2) automated jig, using fine high-quality abrasive. Up to six samples can be used during a lapping/polishing session. Polishing is carried out in steps on a special cloth with a slurry of very fine diamond, ranging in size from 9 to 0.3 microns.

CONTACTS

To apply for the Sample Preparation lab facility please refer to Fabio Lazzari and/or Francesco Vetere Tel: +39 075 585 2609 mail: fabio.lazzari@unipg.it mail: francesco.vetere@unipg.it