HIGH TEMPERATURE LABORATORY

Intro

Our new HT-Lab is designed to fulfil the high-standard requirements for a modern experimental approach to petrology and volcanology.

State-of-the-art and newly designed and in-house built equipment provide the necessary tools for a direct attack on the complexity of petrological and volcanological processes.

Among HT equipment of our laboratory we wish to introduce the Chaotic Magma Mixing Device (CMMD), Anton Paar RheolabQC rheometer, and the Nabertherm furnace HT 04/17.

EQUIPMENTS

Instrumentation

- Chaotic Magma Mixing Device (CMMD)

- Anton Paar RheolabQC rheometer

- High-temperature furnace Nabertherm HT 04/17 (up to 1750 °C)

- 2 High-temperature furnaces Gero HTRV 70-250/18 (up to 1800 °C)

- Lampert PUK 04 Welding Machine

- Breitlander Autofluxer fusion machine

Chaotic Magma Mixing Device (CMMD)

Description

This unique machine allows us to replicate magma mixing in volcanic plumbing systems prior or during volcanic eruptions using natural compositions. It consists of an outer cylinder, filled with the melts of interest, and an inner cylinder, which is located off centre. Rotation of the two cylinders with appropriate protocols trigger chaotic mixing. Fluid-dynamics of the experimental setup is known in advance and established by numerical simulation to match natural outcrops. Numerical simulations are performed using exactly the same geometry of experiments. This device is fully automated and controlled by a computer system allowing to record into log files every step of the experiment for checking and post-processing.

The furnace hosting the CMMD is a GERO high temperature tube furnace for vertical operation up to 1800°C type HTRV 70-250/18.

Anton Paar RheolabQC rheometer

Description

Measuring the viscosity of natural and synthetic silicate melts at high-temperature is of paramount importance to quantify rheology of melts and to design reliable experiments.

This rheometer, fully controlled by a computer system, is an essential instrument to characterize rheological properties of analog and natural melts, also allowing for the production of highly homogeneous glasses.

The furnace hosting the rheometer is a GERO high temperature tube furnace for vertical operation up to 1800°C type HTRV 70-250/18.

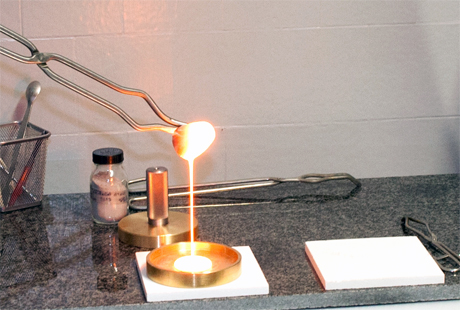

High-temperature furnace Nabertherm HT 04/17

Description

Melting of rock samples is essential for preparation of compositionally homogeneous experimental melts and glasses for experiments. The furnace, working up to 1750°C, allows for complete melting of the samples.

Thermal ramps and profiles can be precisely controlled by computer software to obtain accurate heating and cooling rates.

Lampert PUK 04 Welding Machine

Description

Welding, reparing and building cups and crucibles of platinum and Platinum/Rhodium alloys is essential when performing HT experiments with natural and industrial materials that must not suffer any contamination. Our 5th generation Lampert PUK 04 machine allows for high precision spot welding. This welding machine consistently reproduces high-quality welding results with all materials suitable for welding. Among its high-performance characteristics are the precise position of the spot welds, very low controllable development of heat, welding of even the thinnest materials, welding in a protective atmosphere using Argon gas.

Breitlander Autofluxer fusion machine

Description

Analyses of rock and industrial material bulk samples by XRF, LA-ICP-MS, etc … require the preparation of highly homogeneous glasses. Our programmable Breitlander Autofluxer automatic fusion machine allows for the rapid preparation of samples using platinum/rhodium crucibles and plates to avoid any sample contamination. The fusion system with oxygen enriched flames, the combination of proven burner technology, PLC function and safety control is ideal for producing high-quality samples for high-quality analytical results.

CONTACTS

To apply for the the HT lab facility please refer to Maurizio Petrelli (maurizio.petrelli@unipg.it) and/or Daniele Morgavi (daniele.morgavi@unipg.it) and/or Francesco Vetere (francesco.vetere@unipg.it) Tel: +39 075 585 2609